The Case

Traditional Strat Plan – Generic and hard to put it into action

- 2009: Not profitable due to many Quality and Productivity Problems

- 2011: Profitability achieved but chronic lack of Sales

- 2012: Start of the STRAT KAIZEN™ Strategic Planning and Deployment process

The solution

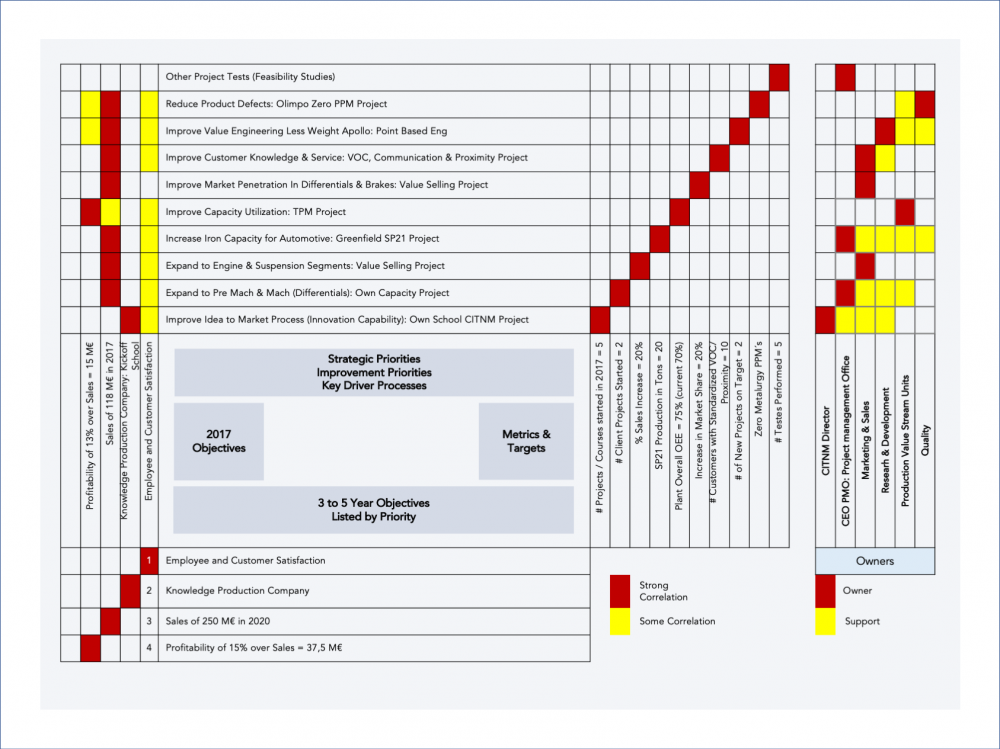

Strat to Action Plan – Hoshin X Matrix

- From 2009 to 2011: Implementation of the KAIZEN™ Operational Excellence Model to achieve Profitability (break even)

- From 20012 to 2016: Implementation of the STRAT KAIZEN™ Methodology with 3 Breakthrough Strategic Initiatives

- KAIZEN™ Culture in all Natural Teams

- VALUE STREAM KAIZEN™ Projects in Product Development, Operations and Sales

- Increase of Production Capacity

The Results

Sustained Increase and Economic Recovery

- Reorganisation into Agile Natural Teams with a Continuous Improvement Daily Culture

- Sales Growth based on Customer Service and Product Innovation

- Profitability increase based on Quality and Productivity